The supply-chain disruptions from the COVID-19 pandemic have forced companies in busy distribution hubs like New Jersey to relax contract terms to address immediate issues, and reshape neglected long-term strategies to establish sources closer to home, Garden State attorneys said.

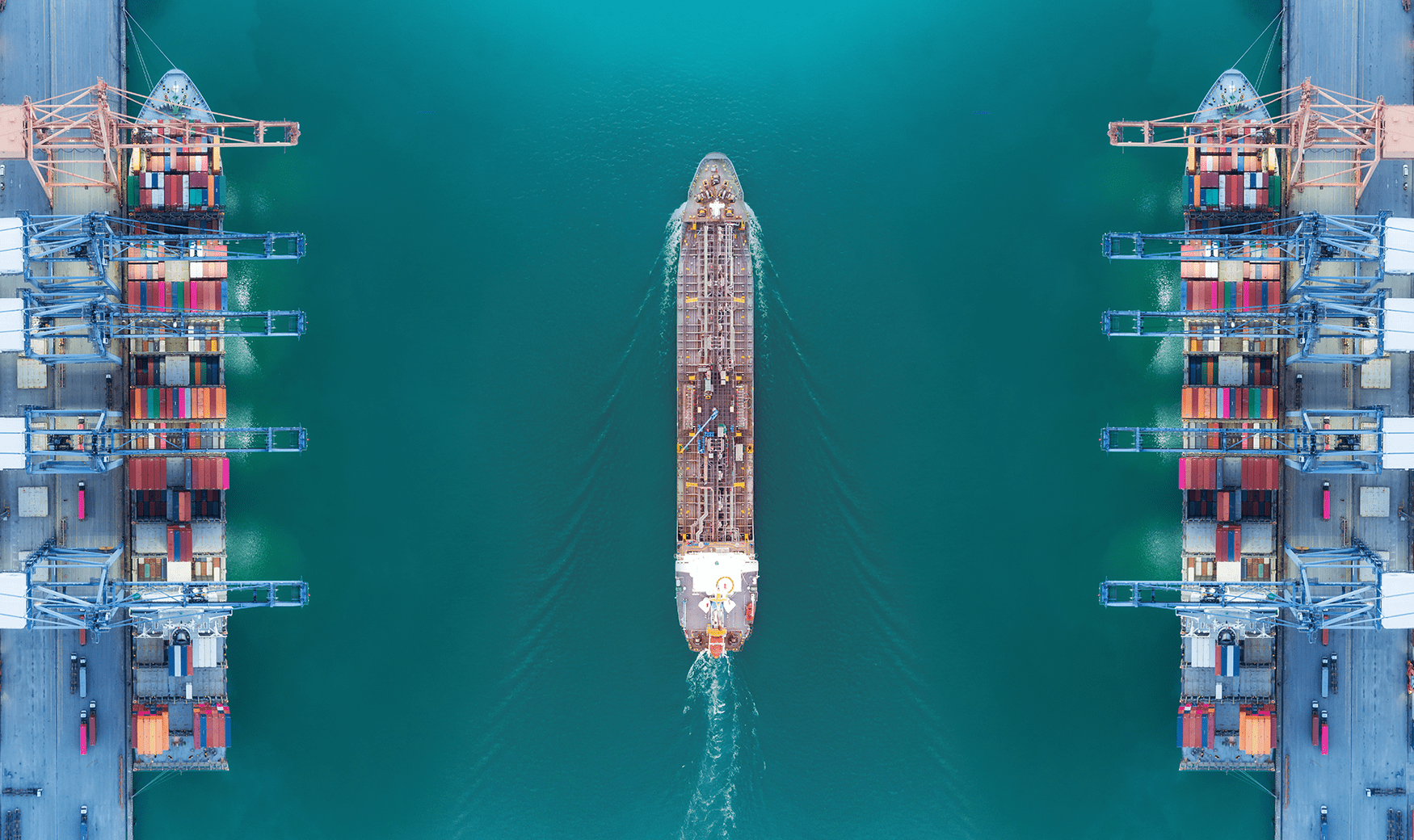

McCarter & English LLP partner Ronald Leibman, leader of the firm’s transportation, logistics and supply chain management practice, quickly got busy in New Jersey, a major center of trade where three major airports, a massive network of roads and railways, a famous turnpike and a shipping port ferry goods to and from a wide swath of the nation and beyond.

A surge of investment in Garden State warehouse space could be one of the long-term effects of the coronavirus, said Leibman, adding that supply chains are crucial to industries like pharmaceuticals and trucking, both of which have a huge presence in New Jersey.

“I really believe that companies that make critical goods are going to maintain a stock of at least essential goods nearby in critical markets, and this is a multimodal crossroad to one of the densest population centers in the world and a logical place to be,” Leibman said.

Companies that continue to look to other countries for supplies and business will be adding pandemics to the list of existing flashpoints — labor strikes, political instability, natural disasters — that could disrupt supply chains, Leibman said.

The disruption caused by the pandemic has highlighted what Leibman considers to be a historic problem with supply-chain strategies, which he said are typically under-reviewed and rarely updated.

Resilience planning, Leibman said, must be as ingrained a part of the corporate culture as a budget, with regular reviewing and updating.